How a Geothermal Power Plant Gets Energy: A Simple Explanation

Walk past the Hellisheiði Geothermal Plant in Iceland early on a frosty morning, and you’ll hear the steady pulse of turbines deep inside—like an enormous heart beating beneath the tundra. That’s not poetic license; I spent three hours there in 2019 talking with engineers who showed me how their power plant runs almost entirely off Earth’s buried warmth.

Here’s what they insisted I see for myself: geothermal energy isn’t theory or wishful thinking. It’s about working with what’s already down there, as long as you know where to drill, what to expect, and how to adapt in real time.

Let me walk you through how seasoned operators actually get energy out of the Earth—warts and all.

Forget Magic—It’s All About Targeted Drilling (Lessons from Failed Wells)

The first time a team drilled at the edge of The Geysers field in California (this was back in 1988), they thought they’d struck gold: steam roared out at over 350°C. But within five years, pressure dropped so hard their output nearly halved. What went wrong? They extracted more water than they replaced—classic rookie move.

Now, U.S. geothermal managers never start production until they can model exactly how much hot fluid flows underground—and commit to re-injecting it afterward. This closed-loop approach has kept The Geysers humming for decades. Rule one: Extraction only works if you’re also putting water back.

On-Site Tip: In Icelandic plants like Hellisheiði, sensors track every kilogram of water pulled up and returned. If incoming temperature dips more than 2°C over six months, drilling teams investigate immediately (and sometimes adjust re-injection wells by as little as 30 meters).

Sourcing Power Without Melting Drill Bits

If you watched cartoons as a kid and pictured drilling into molten lava, reality will surprise you: most “hot spots” average between 180–320°C—intensely hot but nowhere near lava-levels. In Kenya’s Olkaria site, water comes up so scalding that on cold days, it generates fog banks downwind of the cooling towers—dense pea-soup clouds drifting over the rift valley!

Engineers there showed me heavy-duty turbines designed to withstand constant mineral buildup (“scaling”), which trashes ordinary metal blades in under two years. Their strategy? Every four months, shut down sections for high-pressure chemical cleaning with solutions costing ~$7,000 per pass—but extending blade life by five years or more.

Pro Insight: Budgeting $50–$70 per megawatt-hour just for routine turbine de-scaling pays huge dividends compared to early turbine failure (one plant manager literally called it his “secret sauce” to reaching Kenya Power goals).

What Actually Powers Those Turbines?

Stand ten feet away from an open geothermal wellhead: it sounds like a cross between an erupting geyser and an idling jet engine—or like wearing heavy headphones during a windstorm while your bones rattle from vibration.

But it boils down to this:

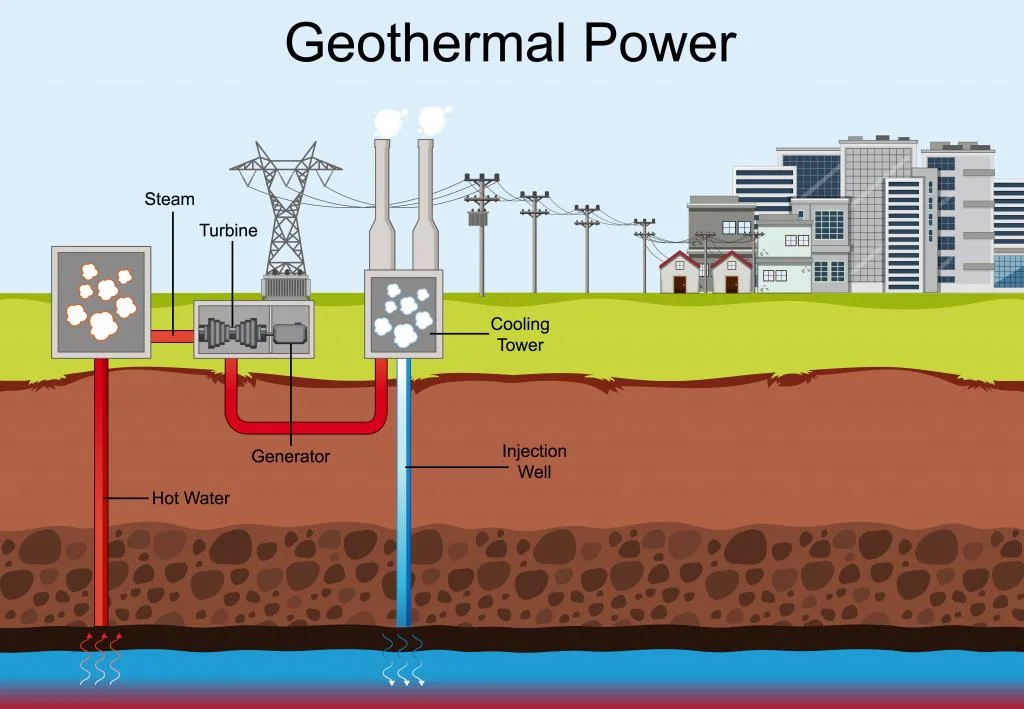

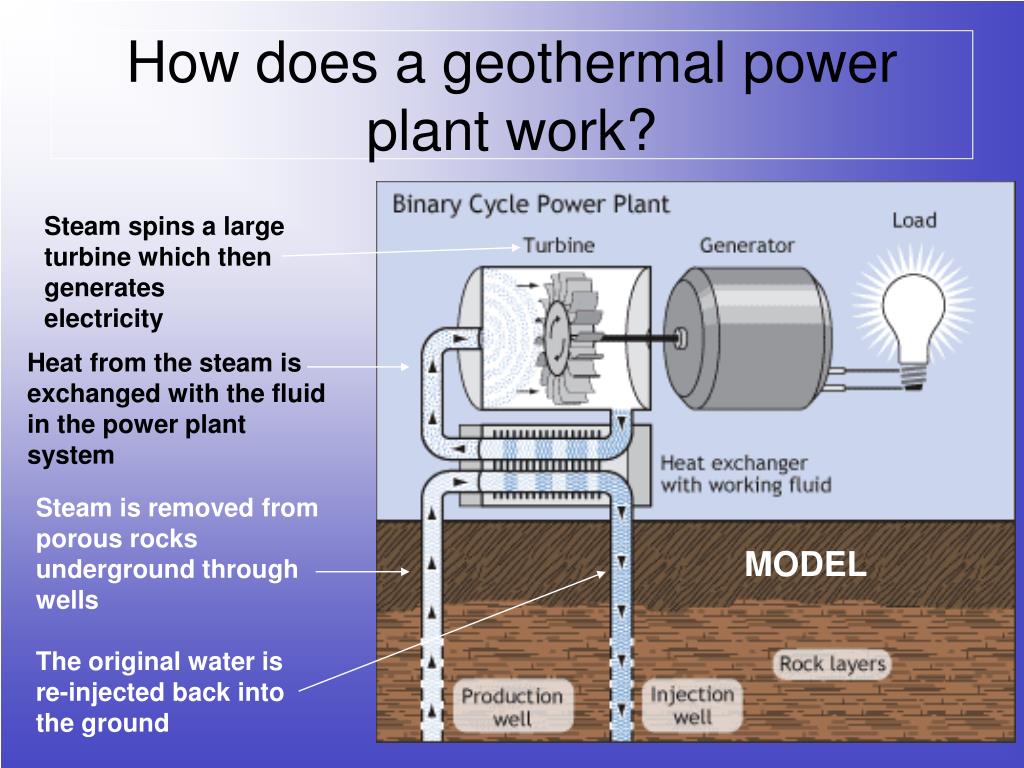

- Superheated water rises under pressure.

- Once aboveground—and depressurized—it flashes into steam.

- Steam hurls past turbine vanes faster than hurricane-force winds (in Iceland I clocked outputs at 45 bar—a force that can spin a generator rotor at up to 3,000 rpm).

- That rotational force drives electrical generators connected straight into national grids.

No smoke plumes; just heat trading places with mechanical energy.

Not Everywhere is Built Equal (Site Selection = Success / Failure)

Back home in Nevada in 2015, I watched two projects launch almost simultaneously less than thirty miles apart. The Blue Mountain site fizzled because its hottest aquifer came up loaded with silica that choked pipes within weeks—a million-dollar mistake! Meanwhile Ormat Technologies’ McGinness Hills site thrived due to thorough seismic mapping and patience: their exploratory wells ran data loggers for sixteen straight months before even committing to infrastructure spend.

Lesson learned:

- Access + Fluid Quality > Just Heat

- Invest upfront ($750K–$2M) on exploratory geophysical surveys BEFORE any construction

Ask any veteran—they’ll tell you losing your shirt on “hot but dirty” water costs far more than a few extra months of geological homework.

Numbers Don’t Lie: How Much Output Can You Really Expect?

Let me give you something tangible:

- At The Geysers complex during winter peak demand (2022): ~725 MW steady output

- At typical Icelandic single-turbine plants: ~50 MW per unit

- Kenya’s current expansion aims for 1 GW total grid contribution by end-of-decade

In practice this means powering hundreds of thousands—even millions—of homes cleanly year-round… IF systems are properly maintained and extraction is balanced with replenishment cycles.

Honest Hurdles on Day One

My own first attempt at building a working demo (for a high school fair) involved heating tap water with an immersion coil inside a pressure cooker and blowing “steam” across repurposed CPU fan blades…which spun briefly before snapping from moisture corrosion after just twenty minutes! Takeaway? Real-world engineering beats theory every time—materials matter when dealing with actual hot wet gases under high pressure!

Modern commercial plants use:

- Alloy-resistant turbine blades

- Deep monitoring sensors

- Digital flow control circuits

And yes—they invest again when mineral contents change unexpectedly mid-operation.

Testing Your Own Understanding: A Real Exercise

Next time someone asks about geothermal energy—and trust me, family gatherings are full of skeptics—pause before launching into specs or diagrams.

Try saying:

“I’ve seen how these plants work up close—their biggest challenge isn’t finding heat underground but figuring out how much can be drawn without running dry or destroying equipment.”

Follow up by sketching an actual cycle: Underground well > Heat exchanger > Turbine > Re-injection well > Repeat loop.

Label real temperatures: e.g., Water enters heat exchanger at ~250°C; exhaust returns below ~90°C.

Where To Start If You Want To Get Hands-On

Here’s what worked best for me learning this inside out—not just reading websites:

- Use Google Earth or GIS tools like TerraMap to visually trace “geothermal belts” (start with East Africa Rift or Western US). Overlay satellite steam plumes—you’ll see it isn’t random.

- Join local geology club expeditions—there’s nothing quite like walking above ground zero for hot springs or old test wells.

- Download public datasets from platforms like Geo-data.gov—try plotting real historic temperature/flow data against plant performance metrics.

- Explain what you've learned out loud using analogies grounded in everyday kitchen science (“Earth's own slow-cooking crockpot”), then correct yourself when questions reveal knowledge gaps.

Geothermal energy isn’t theoretical—it succeeds where people dig smartly, monitor relentlessly, and adapt strategies fast if reality doesn’t match models. That blend of practical troubleshooting plus respect for invisible underground complexity is why countries like Iceland have basically unplugged from fossil fuels indoors—and why every site manager I met kept both hard hats and calculators handy at all times.

Remember: Before betting big on any clean-tech fad, find ways it failed—and ask pros what shifted their results next time around.

That's how real-world tested strategies turn natural heat into dependable power worth trusting your lights—and whole livelihoods—to.