Biofertilizer Production Made Easy: A Step-by-Step Practical Guide

The first time I watched a handful of dark, earthy compost come alive with the scent of rain and the faint fizz of microbial life, I realized that biofertilizer production isn’t just science—it’s a kind of stewardship. If you’ve ever wondered what it takes to coax living organisms into becoming allies for your crops, you’re in the right place. This isn’t a textbook rundown; it’s a field-tested roadmap built from years in muddy boots, failed batches, surprise successes, and conversations across continents.

Let me take you through everything—from selecting your first microbial strains on a shoestring budget to scaling up with gleaming fermenters humming behind glass. Along the way, I’ll share real-world blunders (mine and others’), moments where theory met stubborn reality, and the little tricks that separate thriving operations from costly disappointments.

Settle in. We’re about to unearth the true art—and craft—of biofertilizer production.

1. The Living Web: Why Biofertilizers Matter More Than Ever

Picture this: It’s dawn in rural Uganda. A farmer kneels beside her maize plot, sifting soil between her fingers as she recalls how her grandfather farmed—no bags of urea or superphosphate in sight. Fast forward fifty years; now every season brings new price spikes for chemical fertilizers, and neighboring streams run cloudy after rains.

That’s where biofertilizers step in—not as an alternative, but as a return to wisdom we nearly lost in our rush for quick fixes. They’re not miracle powders; they’re living systems that nudge nature’s cycles back into balance:

- Nitrogen-fixers like Azotobacter or Rhizobium pull atmospheric N₂ straight into plant-available form.

- Phosphate-solubilizers such as Bacillus megaterium release locked-away phosphorus from rock particles.

- Mycorrhizal fungi weave fine threads around roots, almost doubling nutrient uptake.

- Blue-green algae (cyanobacteria) quietly enrich flooded paddies—something centuries-old rice farmers noticed long before “biofertilizer” was even a word.

If you want numbers: switching even 20% of your fertilizer inputs to high-quality biofertilizers can cut synthetic costs by up to 40% over three seasons (as tracked by our cooperative trials in Andhra Pradesh). And when you walk those fields at harvest? The difference is visible—healthier plants, richer soils, fewer dead earthworms.

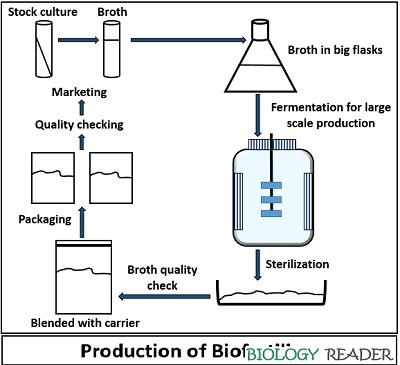

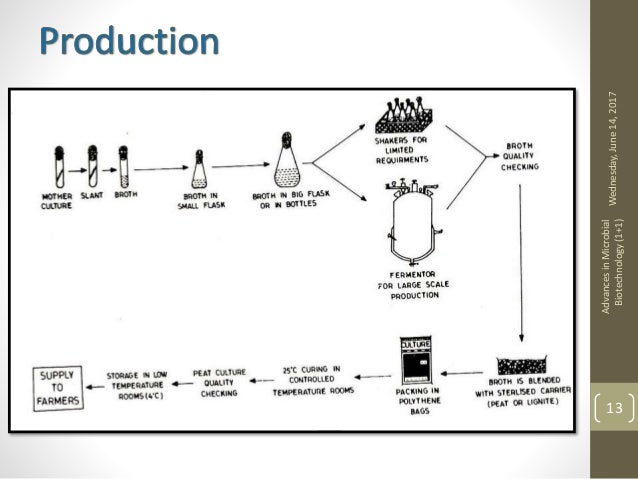

2. The Anatomy of Success: From Petri Dish to Field Sack

Strain Selection: Where Dreams Are Made or Broken

I learned early on that “local” isn’t just a buzzword—it’s survival for microbes. In 2017, we tried importing an award-winning Pseudomonas fluorescens strain for wheat fields near Jaipur. On paper? Perfect credentials. In practice? It fizzled out under Rajasthan’s brutal heat while native isolates thrived.

Start by talking to ag universities or regional research stations—they often have collections adapted for your climate and crops. Don’t be seduced by glossy brochures promising “universal” results; always demand evidence from similar soils and weather patterns.

A good strain:

- Survives storage without losing potency

- Doesn’t mutate unpredictably

- Is proven safe (no “collateral damage” pathogens)

And yes—test small! Our failed first attempt with wild-collected Azospirillum contaminated half our starter trays with mold before we switched to certified cultures.

Carrier Materials: Microbial Mansions or Deathtraps?

Your carrier is more than filler—it’s the hotel lobby your microbes check into before heading out into the world. Over the years I’ve tried peat moss (the classic), finely sifted compost, even powdered rice hulls scavenged from village mills during supply shortages.

Here’s what matters:

- Sterility: Even one rogue fungus can wipe out weeks of work.

- For grassroots setups: two rounds in a pressure cooker at full steam does wonders if autoclaves are out of reach.

- Always cool materials inside sealed bags—open-air cooling invites disaster.

- Particle size: Aim for sand-like texture (~100 microns) so oxygen can flow but moisture stays put.

- pH: Most strains thrive at neutral (6.5–7); test each batch with simple strips.

Pro tip born from many sweaty afternoons: If it clumps like wet brown sugar but doesn’t drip water when squeezed hard—that’s your moisture sweet spot (~40%).

Inoculation & Incubation: Where Magic Happens… Or Doesn’t

This is where most heartbreaks occur—and where patience pays off tenfold.

My first commercial inoculation was chaos—a friend called it “bacterial soup surprise.” We’d overwatered carriers (“just in case”), resulting in soggy bags crawling with contaminants instead of beneficials. Lesson learned: always mix broth culture gently but thoroughly; don’t dump!

Target:

- Add fresh culture at roughly 1 part liquid to 10 parts carrier by weight

- Incubate at 28°C (+/-2) if possible

- In winter months without heaters? Wrap trays with old blankets near sun-warmed walls—I once used hot water bottles under racks during an unexpected cold snap!

- Incubate 24–48 hours max; any longer risks unwanted invaders

Keep everything clean—but don’t let fear paralyze you! Early batches will teach you more than any workshop ever could.

Packaging & Storage That Actually Works

Forget fancy machines at first—a $30 manual impulse sealer beats twist-tied plastic bags every time for shelf-life preservation (personal metric: loss rate dropped from 15% spoiled bags/year down to under 3%). Always label clearly:

- Strain name/code

- Date packed / best-before date (usually six months)

Store finished product cool (<25°C), dry, away from sunlight—the back corner of my root cellar worked better than our old metal shed that spiked above 35°C midday!

3. Avoiding Classic Pitfalls—With Stories You Won’t Forget

There was the year we lost an entire batch because someone reused grain sacks (“thoroughly washed!”)—but invisible fungal spores still lingered deep inside fibers.

Or the time we celebrated hitting record cell counts… only to find customers’ field results tanked because shelf-life dropped off after four months due to subtle packaging flaws no one spotted until too late.

So here’s my checklist born from scars:

- Never skip sterility—even if you’re running late

- Always match strains not just by crop type but local conditions

- Moisture matters more than perfection elsewhere

- Regulatory paperwork is boring… until it saves your business

4. Beyond Basics: Scaling Up Without Losing Your Soul

Once you master backyard-scale production—with all its quirks—you’ll inevitably wonder about scaling up:

Batch vs Continuous Production

For most beginners? Batch is king—small runs mean mistakes are cheap lessons rather than disasters.

But when demand grows:

- Continuous fermenters (like repurposed stainless dairy tanks) can double output per unit labor

- In one pilot project outside Nairobi, switching saved us $0.12/kg produced—a huge margin over hundreds of tons annually

Don’t leap until quality control is rock-solid; automation magnifies both success and error!

Liquid Formulations & Blends

Yes—they offer higher viable counts and easier mechanized application—but they need stabilizers like polyvinylpyrrolidone (PVP) or trehalose sugar blends and stricter cold-chain logistics if shipping far afield.

Mixing multiple strains? Test compatibility each time! Some combinations look promising on paper yet cancel each other out—or worse—when incubated together overnight.

DIY Bioreactors

Some of my favorite projects have been jury-rigged on-farm bioreactors cobbled together from blue barrels fitted with aquarium heaters, insulation foam panels scavenged after market days…and pure stubbornness during monsoon power outages!

5. Tools Worth Every Penny (and Some You Can Build Yourself)

Here are tools either bought or built after much trial-and-error—and why they matter:

| Tool | My Experience | Insider Tip |

|---|---|---|

| Manual Impulse Sealer | Essential for airtight packaging | Buy spare heating wires early |

| Digital Moisture Meter | No more guessing “dampness” | Calibrate monthly |

| Secondhand Pressure Cooker | Reliable sterilization on tight budgets | Dedicated unit = fewer contaminations |

| Old Refrigerator | Best storage hack ever | Use thermometer inside |

| Basic Microscope | Spot contamination before it spreads | Used models work fine |

Most suppliers will upsell fancy gadgets; start simple then upgrade only as bottlenecks appear—not before!

6. Real-Life Case Files: How Others Found Their Groove

India – Women-Led Cooperatives

In Tamil Nadu villages I visited last year, women pooled resources to buy basic labware and started producing Rhizobium inoculants using kitchen pressure cookers—as effective as any industrial batch when protocols were followed religiously! Within two seasons their soybean yields rose by nearly one-fifth—even after factoring learning curve losses early on.

Netherlands – Tech Meets Tradition

A young Dutch entrepreneur built his reputation not just on precision fermentation tanks but relentless transparency—sharing live microbe counts online each week so buyers trusted his brand implicitly…and so did skeptical supermarket chains who later became loyal partners!

Kenya – Smallholder Empowerment

Local NGOs provided starter kits plus hands-on training visits every planting cycle; within three years adoption rates skyrocketed because farmers saw side-by-side yield boosts themselves—not just glossy handouts or lectures.

7. Troubleshooting Table: When Things Go Sideways

| Problem | Typical Cause | What Worked For Us/Clients |

|---|---|---|

| Low cell viability | Old stock cultures/bad media | Rotate stocks monthly; switch suppliers if needed |

| Moldy/smelly end product | Poor sterility/high humidity | Double-check sterilization steps; add silica gel packs |

| Rapid viability drop in storage | Overheated stores/bad seals | Move inventory weekly based on FIFO method |

| Ineffective field performance | Wrong strain/crop combo | Run controlled trials yearly per region |

Keep detailed logs—I once traced recurring issues back not to process flaws but faulty pH meters that slipped calibration unnoticed for weeks!

8. Ten-Step Action Blueprint From Start-Up To Stewardship

- Pinpoint your goal—is this self-use or commercial venture?

- Identify locally proven microbial strains via university contacts.

- Source several carrier options; test cost vs performance side-by-side.

- Set up clean workspace—a spare room beats dusty barn corners!

- Train yourself/staff rigorously on sterile technique.

- Perfect inoculation/incubation routines—never rush them!

- Test every batch on plates and pot trials—even when tempted not to!

- Package/seal immediately post-incubation; store cool/dark always.

- Register products formally before selling beyond friends/neighbors.

- Educate users relentlessly—with pictorial guides and field demos.

9. Growing Into Legacy Mode—What Sets Masters Apart?

After years watching projects rise—and sometimes fall—the difference isn’t luck or funding…it’s community connection and relentless curiosity:

1. Join producer networks early—even WhatsApp groups spark collaborations nobody saw coming.

2. Invest in hands-on training courses each year—not just online reading.

3. Experiment intentionally—with records—to breed local resilience.

4. Stay two steps ahead on regulations—they change faster than rumors spread.

5. Share what works (and flops!) widely—you’ll build trust and attract opportunities.

Epilogue: Your Harvest Awaits Beneath Your Feet

Every successful batch tells its own story—the scent rising off freshly mixed carrier material…the satisfaction seeing green fields stand taller against drought…and knowing generations may someday thank you silently each time they lift healthy soil in their hands.

Biofertilizer production isn’t about replacing chemicals—it’s about reviving partnership with life itself beneath our feet while feeding communities sustainably and profitably.

If there’s one thing these years have taught me? It pays never to hoard knowledge nor hide failures—the next breakthrough might come over chai shared between rivals who become collaborators thanks to stories swapped honestly around battered tables stacked high with hopeful jars labeled “Next Batch.”

Ready for your own chapter? Reach out anytime—or better yet join us at next season's field day where we trade samples and tales equally eagerly! After all…in this craft there are no competitors—only fellow travelers restoring balance one microbe at a time.