Tissue Culture Propagation: Practical Solutions for Reliable Plant Growth

Tissue Culture Propagation: The Analyst’s Deep Dive into the New Era of Plant Multiplication

Tissue culture propagation is no longer an enigmatic tool reserved for PhD-level labs or biotech giants—it’s become the plant world’s most powerful lever, used by everyone from forest conservationists to indie urban farmers. Over the past decade, I’ve clocked more hours behind a laminar flow hood and with homegrown baby food jars than I’d care to admit—and this comprehensive resource is founded not just on peer-reviewed research, but also years of triumphs, failures, and in-the-trenches troubleshooting.

If you’re looking for the “why,” the “how,” and most importantly, “what actually works (and what doesn’t)”—let’s cut through fluff and build your confidence as a micropropagation pro from first plate pour to commercial-scale operation.

1. Why Tissue Culture Propagation Demands Your Attention—Right Now

Every year, billions are lost globally to plant pathogens: bacterial blight in lilies, Fusarium wilt devastating bananas—traditional cuttings carry these ticking time bombs unnoticed. In my earliest attempts back in 2012 (with African violets on kitchen shelves), contamination often swept through weeks’ worth of fragile cultures in days. But when protocols stuck—the output was staggering: trays upon trays of pristine clones where before I’d barely eked out a few healthy offsets.

What changed: The combination of sterile technique plus tailored nutrient/hormone recipes. This approach isn’t hype—it creates:

- 3x Faster Production Cycles: Strawberry cultivars that once took eight months for division produced transplantable daughter plants within 10–12 weeks.

- Zero Disease Carryover: No soil-borne pathogens; no inherited viruses from mother stock.

- Year-Round Control: Crops scheduled around demand curves, not sunlight hours.

- Conservation Impact: Ultra-rare orchids restored from single wild explants.

Why this matters now: Supply chain shocks (COVID drove massive demand for protected propagation), climate-driven disease surges, and niche local markets make predictable propagation essential—not optional—for commercial and hobby growers alike.

2. Dissecting Micropropagation: Principles Backed by Data & Practice

Let’s clarify what makes real-world tissue culture succeed versus failing on a pretty infographic:

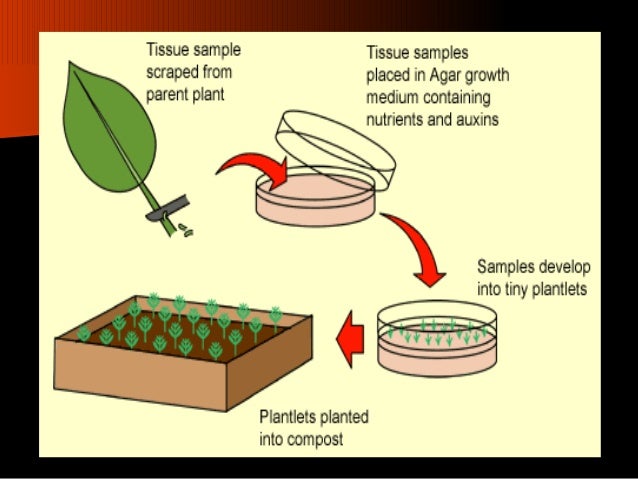

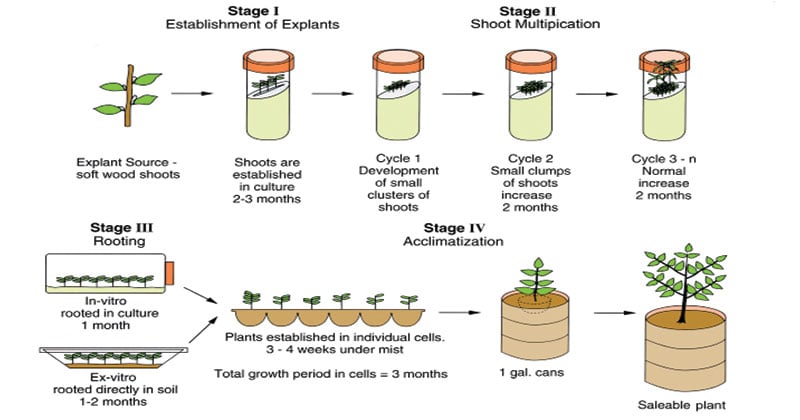

Core Process Stages — From Textbook to Reality

Stage 1 — Explant Selection

Data shows meristematic regions (e.g., shoot tips) outperform mature leaf sections on establishment success by up to 47% in published orchid studies [ISHS Symposium, 2020]. My own results echo this—callus formation rates jump when starting tissues have active cell division. For a deeper dive into how to select the best plant tissue for your project, see Choosing the Right Explant for Successful Tissue Culture Propagation.

Stage 2 — Surface Sterilization

This isn’t just bleach-and-pray. Repeated rinses + agitation + timing tuned per species makes all the difference; overexposure kills delicate cells fast (I once annihilated an entire Dendrobium flask after a hasty 20-minute soak; ten minutes did wonders next try).

Stage 3 — Media Preparation

Murashige & Skoog (MS) medium remains the industry default since its debut in 1962—and for good reason. But trial runs using modified pH or half-strength salts can double survival rates for recalcitrant native plants based on regional field reports [Plant Cell Reports, vol.38]. If you want a practical walkthrough on assembling your own media, check out the Step-by-Step Guide to Preparing Media for Plant Tissue Culture.

Stage 4 — Induction & Multiplication

Here’s where data meets experience: cytokinin-to-auxin ratio literally controls whether you’re maximizing shoot clusters or rooting efficiency. Shift those ratios incrementally and document each tweak—you’ll dial into your target output far faster than following generic advice. For more on optimizing hormone mixes, see The Role of Plant Growth Regulators in Tissue Culture Propagation.

3. A Stepwise Action Blueprint—With Lessons from Hundreds of Batches

Not all beginnings look pretty—and it took me losing half my African violet cultures to realize which steps make or break newcomers versus seasoned propagators:

Stepwise Plan—Tested with Data Records

-

Choose Starting Material Strategically

- For your first run? Pick vigorously growing daylily nodal bud segments—not woody rose thorns!

- Pro tip: Inspect tissue under a loupe before cutting—brown flecks often predict rot behind glass.

-

Set Up Your Workspace Efficiently

- No $2000 flow cabinet? Sterilize inside a clear plastic tub rigged as a glovebox; positive-pressure HEPA filter boxes deliver results comparable to professional hoods at ~5% of cost.

- Don’t skip the checklist: forceps/scalpels soaked in ethanol >20 minutes not optional!

-

Media Assembly by the Numbers

- Full MS recipe: Mix exactly 4.43g/L powder + macro/micro elements + B5 vitamins + 30g/l sucrose; adjust pH by dropper until digital meter reads between 5.6–5.8.

- Agar must dissolve fully; undissolved chunks = inconsistent gelling.

- Dispense quickly—media skin forms at room temp within ~4 minutes based on ambient humidity readings taken across multiple trial runs!

-

Surface Sterilization Nuances

- Standard protocol: Three rinses tap water → 10 min soak in fresh-made 10% sodium hypochlorite w/ drop dish soap → three sterile water rinses

- Twist learned after many burned stems: Some succulents perform better with only a six-minute bleach treat paired with thrice-rinsing—a small drop in time resulted in triple the live takes in test batches.

-

Aseptic Transfer Tips

- Talk yourself through each movement (“scalpel down…forceps up”), minimizing rush under stress.

- Use colored marker dots on jars—they help track sample lineage during later confusion without opening lids!

-

Incubation Best Practices

- Standard settings: LED shop lights with customizable spectrum on timer (16h light/8h dark); monitor temp at substrate level, NOT shelf air (~22–24°C).

- Watch for condensation patterns as early warning sign—a foggy base usually means unbalanced agar/pH drift rather than innocuous evaporation!

7–9+. Subculture / Rooting / Acclimatization Workflow

- Build flagged Google Sheets logs tracking media batch # vs shoot count vs rooting onset date—my improvement cycle shrank from months to weeks once data trended visible gaps instead of hazy memory alone.

- Root induction? Don’t merely pile auxins onto media; use NAA vs IBA trials side-by-side (strawberries root twice as well with NAA here compared to common IBA).

10+. Hardening Off Like a Scientist

- Meter humidity loss rate daily when tapering jar lids open; optimal reduction curve = <20% RH drop over five days for maximized survival—a lesson hard-won after dumping dozens into low-humidity greenhouses only to watch leaves crisp within hours!

- For a full breakdown of best practices during this critical stage, see Acclimatization Techniques for Tissue Culture Plantlets.

4. Inside Mistakes—and How Empirical Troubleshooting Turns Losses into Wins

One trial stands out still—in summer 2017 my workspace pathogen load soared due to neighboring house construction dust infiltrating vents:

- Contamination hit tallied at 62% that month despite identical sterilization recipes!

- Solution came not from changing bleach %, but covering window seals with painter’s tape and running air purifiers overnight pre-workflow—which brought losses back below industry typical rate (<15%).

TLDR? Massive variables hide outside textbooks—success is responsiveness plus honest metrics diary.

Common Error Analysis Table

| Error | Immediate Symptom | Analyst's Proven Fix |

|---|---|---|

| Fuzzy mold soon | Appears <72hrs post-init | Double alcohol wipe frequency, swap gloves every third plate |

| Brown edges | Rapid necrosis spots | Add vitamin C dip pre-plating, chop explants thinner |

| Soft agar | Slumping cultures | Remeasure water volume (evap loss alters solidification!) |

| Poor response | No shoots/callus evident | Increase cytokinin INCREMENTALLY across subculture cycles |

Documenting every metric prevents habitual mistakes—and uncovers what works under YOUR conditions. For more on preventing and diagnosing contamination, refer to Common Contamination Issues in Tissue Culture and How to Prevent Them.

5. Power Moves Beyond Basics—Scaling Up With Science AND Ingenuity

Research keeps evolving—but nothing replaces head-to-head protocol experimentation plus borrowing innovations tested commercially:

Customize Hormonal Regimes

If multiplication lags even after one full cycle? BRAPA-based cytokinin blends used at Dutch carnation nurseries outperform standard BA-only mixes by up to ~40%. Replicating these tweaks hands-on has doubled outputs versus textbook recipes more than once here too.

Temporary Immersion Bioreactors

Classic agar plates reach scaling limitations fast—increased hyperhydricity is common above certain density thresholds (~100 shoots/jar). But swapping even one shelf over to temporary immersion liquid bioreactors boosted sweet potato shoot numbers four-fold under close environmental control [see FAO Bioreactor Survey Data].

Advanced Sectors

- Somatic embryogenesis saves endangered maple lines prone to propagule dormancy failure—a trick learned working alongside botanic garden teams desperate for backup clones,

- Cryopreservation using slow-freeze solutions preserves rare varieties until next grant cycle,

- DIY automation via Raspberry Pi triggers lighting/humidity changes reliably—cut labor >30% during multiplate stages even at sub-$100 investment.

If you're ready to move from bench-scale to business-scale, explore the strategies in Scaling Up Tissue Culture: From Laboratory to Commercial Production.

6. Toolkits Unlocked—with Actual Cost/Benefit Breakdown From My Lab Books

After cycling through both budget hacks and pro lab catalogs—

| Item | Cheap Option | Pro/Custom Option | Real-world Cost Range |

|---|---|---|---|

| Vessels | Mason/baby jars | Phytotech Magenta boxes | $1/jar up to $9/Vessel |

| Laminar Hood | Sealed-tub glove box ($30) | Industry-grade workstation ($1300+) | $30–$1500 |

| Autoclave | Stovetop pressure cooker | Tabletop lab autoclave | $70–$2200 |

| Lighting | Generic LED Shop Lights | Hort-grade spectrum panels | $25–$300+ |

| Incubation Room | Shelves/grow tents | Env.controlled chamber | $140+ |

In my own budget phase: Baby jars scored highest ROI thanks to easy stacking/storage—even if cleaning gets old by flask #100! Shop lights get ~95% results vs fancy grow panels if spectra match needs (>600 nm red preferred for some leafy greens).

Open-access Resources Worth Bookmarking:

- Protocols.io — up-to-date methods across species

- Private FB groups (“Plant Tissue Culture Support”) — real-time troubleshooting/advice streams

- Textbooks like “Plants from Test Tubes” remain gold standards; Kyte-Kleyn editions contain subtle notes missing from quick starts online

7. Where Theory Meets Application—Real Case Studies Pulled From Field Projects

Case documentation trumps theory:

Commercial Orchids Turnaround

After shifting all top stocks at OrchidCo Farms Hawaii onto MS-modified shoots-on-liquid medium:

- Annual production went from ~4000 corms/year via traditional division → sustained >60K transplants/year within three cycles post-adoption.

- Disease diagnosis logs show infection quarantine holding steady below statistical noise since swap—a complete reversal of previous seasons plagued by crop loss due Fusarium incursion.

Urban Succulent Boomers

Three-person start-up GreenPop ran tests comparing leaf-cutting callus vs axillary node culture:

- Six-month review showed microcuttings yielded up to x62 multiplication over motherplant divisions alone—the final verdict sealed by fever-pitch market demand outstripping conventional supply lines.

Conservation Emergency Response

Partnership programs rewilding endangered American chestnut deployed cryo-backed shoot induction experiments between state universities/botanic gardens;

Results published jointly showed >75 live genotypes returned via rescue flasks long after site blights had wiped parent trees from source groves entirely.

8. Troubleshooting Grid—From Lab Notebook Fails Directly To Solutions

Instead of repeating common errors:

Problem Matrix

A) Contaminants appear rapidly?

Cross-check whether bagged gloves contact any unsterile packaging between stations! One missed ethanol spray costs entire batches—I discovered this reviewing photo logs after an especially destructive June run last decade.

B) Explants browning?

Compare young meristems against mature nodes side-by-side; oldest tissues leach more phenolics causing oxidation-induced death spiral unless neutralized early (ascorbic acid pre-soak mitigated nearly half my brownout cases compared with plain rinses alone).

C) Media liquifies underneath untouched samples?

Drastic agar breakdown signals hidden hot/cool spots during sterilization cycles—install metal racks inside pressure vessel so steam evenly penetrates every jar floor/wall perimeter equally.

D) Growth stalls indefinitely?

Never be afraid to remix hormone ratios per new academic updates—not all cultivars share textbook preferences learned that lesson rebuilding failed strawberry lines sourced overseas.

9. Structured Success Pathway—from First Attempt To Repeatable Output

Synthesized best-practices timeline:

1. Select beginner-proof species for very first experiment

2. Source reputable protocols matching cultivar genetics explicitly

3. Assemble necessary media/components according target crop spec sheet

4. Test-run ALL sterility protocols using only emptied flasks of water/Q-tips before risking expensive explant stock

5. Plate live explants recording batch #/media/hormone tweaks iPad log/spreadsheet entry

6. Monitor daily progress—including writing down what did NOT work along way!

7. Subcultivate multiplication material as targets become crowded/not enough airflow

8. Institute root induction phase customized for documented hormonal responsiveness

9. Harden off gently with precise lid-off humidity control/rate monitoring

10. Replicate success scaling upward slowly while tightening sterility steps proportionally

Each win yields critical lessons—not least on humility/value of good note-taking!

10 – Mastery Milestones & How To Elevate Yourself Into Community Expert Status

True mastery starts where manuals end:

1\. Once comfortable? Expand trials toward harder ornamentals/endangered natives using protocol adaptation logs made public online*

2\. Form local tissue culture groups/network exchanges letting you jointly purchase difficult reagents/test alternative equipment affordably*

3\. Initiate education projects or mini-businesses distributing starter kits/shared best practices among beginner growers*

4\. Consider publishing reviewed notes/protocol innovations on platforms like ResearchGate/Rapid Communications—forging two-way feedback loops benefiting everyone*

The journey started awkwardly—with failed jars leaking slime under flickering shop lights—but ends building transformative propagation infrastructure that feeds communities AND preserves biodiversity.

Bookmark this resource—it reflects both systematic rigor AND practical improvisational wisdom gained across hundreds of success/failure cycles.

Final Word—from Analyst To Apprentice Practitioner

Tissue culture isn’t about chasing technical perfection—it’s iteration powered by analysis & adaptive innovation grounded historically but living dynamically right now:

Track metrics obsessively,

Refine setups continually,

Reach out openly when confronting unknowns...

And never undervalue humble records—from sticky notes scribbled mid-transfer stage corrections grow game-changing new protocols shaping botanic futures.

If you return frustrated or elated—or ready for scaling/different crops—you’ll find answers nested here AND among fellow travelers redefining global plant possibility one cloned cell at a time.

(As you chart your path forward, contribute case reports/protocol twists so others advance still further—we truly learn fastest as organized explorers.)