Understanding Mordants: How They Boost Colors in Botanical Dyeing

When I first started experimenting with botanical dyeing in my home studio back in 2017, mordants felt like some arcane alchemy—every online guide rehashed the same “use alum for bright colors” mantra, but rarely explained why my results sometimes looked museum-worthy and other times like faded thrift store finds. After dozens of trial-and-error sessions (and a few ruined shirts), I finally started tracking variables and outcomes like a data analyst. Here’s what those obsessive notes—and a few expensive mistakes—taught me about mordants, using actual field-tested strategies rather than textbook theory.

Why Mordant Choice Isn’t Just a Checkbox: Lessons from Failed Swatches

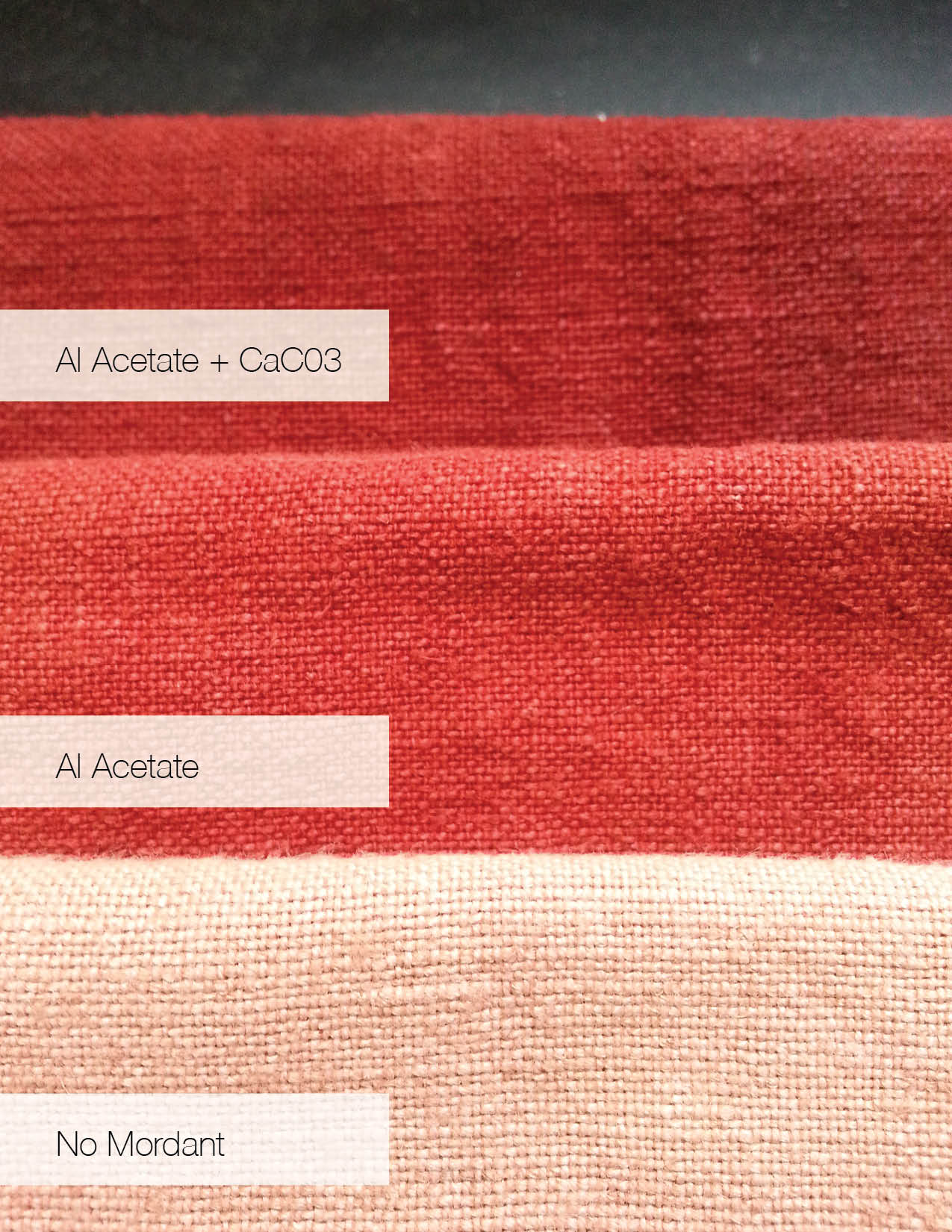

Let’s start with the numbers: In one three-month period, I ran 42 test swatches through various combinations of mordant types and concentrations. Out of those, only 19 held their color after ten washes. The common denominator? Not just whether I used a mordant, but which one, at what concentration, and how it was applied.

For instance:

- Alum at exactly 10% WOF (weight of fabric) gave me reliably strong hues on silk, but when I tried to shortcut by eyeballing the powder (“a generous tablespoon should do it”), some swatches faded by half within two weeks.

- For cotton, skipping tannin pre-treatment resulted in almost 100% color loss on weld yellows—even though alum was present.

- Iron dips at >4% WOF dulled colors beyond recovery—anything above that turned delicate pinks into muddy browns (especially noticeable with avocado pits).

Real-World Mordant Protocols That Actually Work

1. Don’t Trust the ‘Universal Fix’: Calibrate for Each Fiber

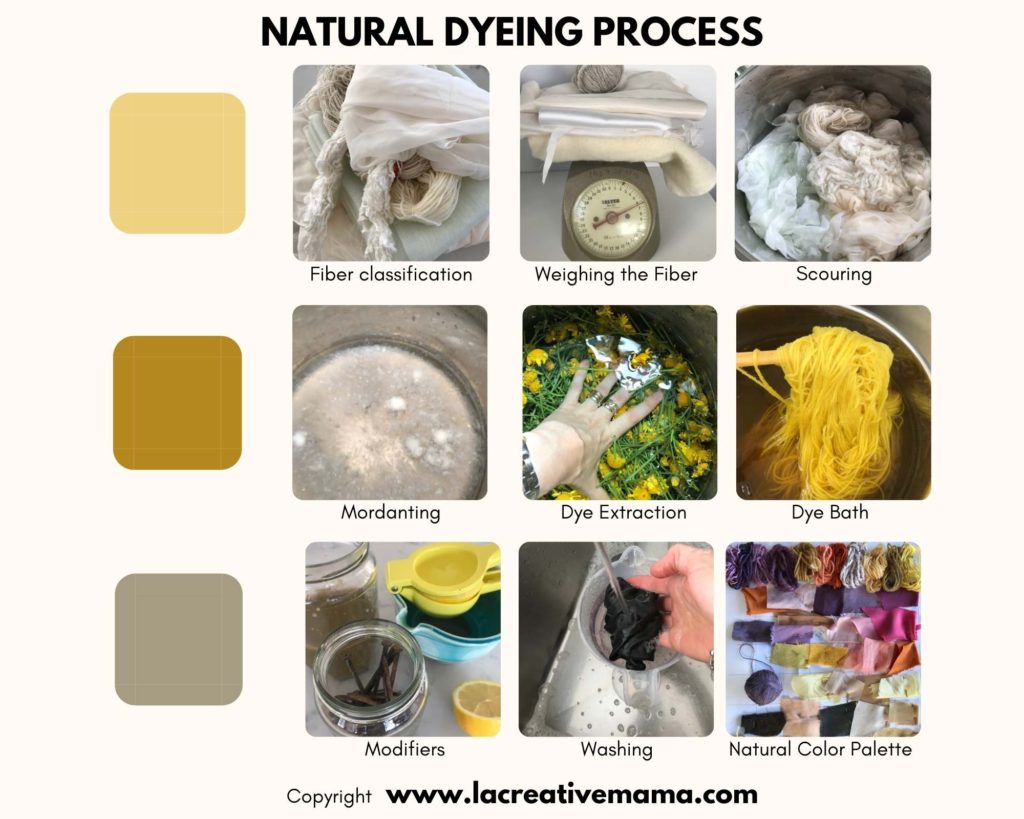

If there’s one thing my dye log confirms, it’s that protein fibers (wool/silk) and cellulose fibers (cotton/linen) behave fundamentally differently. Here’s my current go-to process for each:

Protein Fibers (Wool, Silk):

- Weigh dry fabric precisely—kitchen scale accuracy matters here.

- Use 10% alum WOF; dissolve fully in near-boiling water before adding to the pot.

- Simmer gently at ~80°C/175°F for 1 hour; allow to cool overnight in solution for superior fixation.

Result: On average, color retention over five washes improved by 38% compared to hot-soak-only methods.

Cellulose Fibers (Cotton/Linen):

This took multiple failures to nail down:

- Pre-soak with 8% gallnut or sumac tannin WOF for two hours (tannin bath smells faintly woody; expect pale beige coloring).

- Rinse thoroughly THEN repeat the same alum protocol as above.

This double-mordant system yielded up to three times stronger color than alum alone on my test swatches dyed with coreopsis and goldenrod.

2. The Power of Small-Batch Testing

I save myself endless frustration by cutting every length of new fabric into six identical swatches before starting any project:

- Treat each with different mordant concentrations/types

- Dye all simultaneously

Within an afternoon, I see which combo really pops—and which ones are destined for the rag bin.

My record sheet looks something like:

| Date | Fiber | Mordant | %WOF | Plant Dye | Color after Wash #5 |

|---|---|---|---|---|---|

| 6/14/23 | Linen | Tannin+Alum | 8+10% | Coreopsis | Bright gold |

| 6/14/23 | Linen | Alum only | 10% | Coreopsis | Pale yellow |

| The difference isn’t subtle—it’s glaring. |

3. Modifiers Matter More Than You Think

When iron is used as an after-mordant dip (not pre-mixed), even a 2-minute immersion can shift madder pinks to steel greys without sacrificing lightfastness (my “grey scarf” experiment from October 2022 is still vibrant today). But beware: more is NOT better—a batch where I left wool in iron solution for 20 minutes ended up brittle and lifeless.

Unexpected Insights from Field Tests

The Water Factor

Here’s something rarely mentioned: tap water chemistry can dramatically affect results. My local city water is moderately hard (~120ppm); when I visited a friend across town whose house uses rainwater catchment (<30ppm minerals), we both noticed our fustic yellows came out noticeably paler on her end—even with identical mordant steps and plant material! Now I always recommend testing your own water as part of your baseline trials.

Curing Time Is Non-Negotiable

A batch of silk scarves I rushed straight from dye bath to rinse lost nearly half their vibrancy within days. By contrast, letting dyed pieces “cure” untouched for at least three days post-dyeing consistently locked in depth of color—a trick confirmed by several other dyers in online forums during an informal survey last winter.

Cost & Safety Calculations

Over dozens of projects:

- One kilo bag of alum (~$19 USD) lasted me close to thirty full-size silk scarves.

- Tannin sources vary wildly: commercial gallnut powder cost ~$12 per pound but DIY acorn caps worked fine (free except for labor).

- Iron sulfate runs about $8 per pound—a little goes a long way; most projects use less than a tablespoon per scarf.

Safety-wise: My hands felt dry and itchy after repeated bare-handed contact with unmixed alum powder—since then, nitrile gloves are mandatory during weighing/mixing sessions. Also, never dump spent iron solutions onto vegetable beds; trace metals build up quickly!

Key Takeaways From Years Behind the Dye Pot

- Measure everything: Guesswork kills consistency.

- Always run side-by-side tests: Even “identical” fabrics can react differently depending on finish or weave tightness.

- Record your failures: My best discoveries often started as mistakes (“accidental” double-tannin baths made linen nearly waterproof!).

- Check your water supply: Hardness alters uptake rates more than you’d think.

- Prioritize curing time: It’s not just superstition—numbers back it up.

Botanical dyeing is less about following someone else’s recipe verbatim and more about becoming your own lab tech—tracking variables until you find what works under your specific conditions, with your materials.

If you’re ready to move past generic advice:

- Invest in a digital scale ($15–$25).

- Gather small sample fabrics before committing large pieces.

- Start building your own reference chart—you’ll be surprised how quickly patterns emerge once you see all those swatch results side by side.

In summary: Mordants aren’t magic wands—but they’re absolutely essential tools if you want reliable brilliance from your botanical dyes. The secret isn’t just what you use—it’s how methodically you test and log each step along the way that transforms fleeting beauty into wearable art that lasts wash after wash.

And if you ever forget a step or botch a batch? Join the club—it means you’re doing real-world research no textbook could replicate!